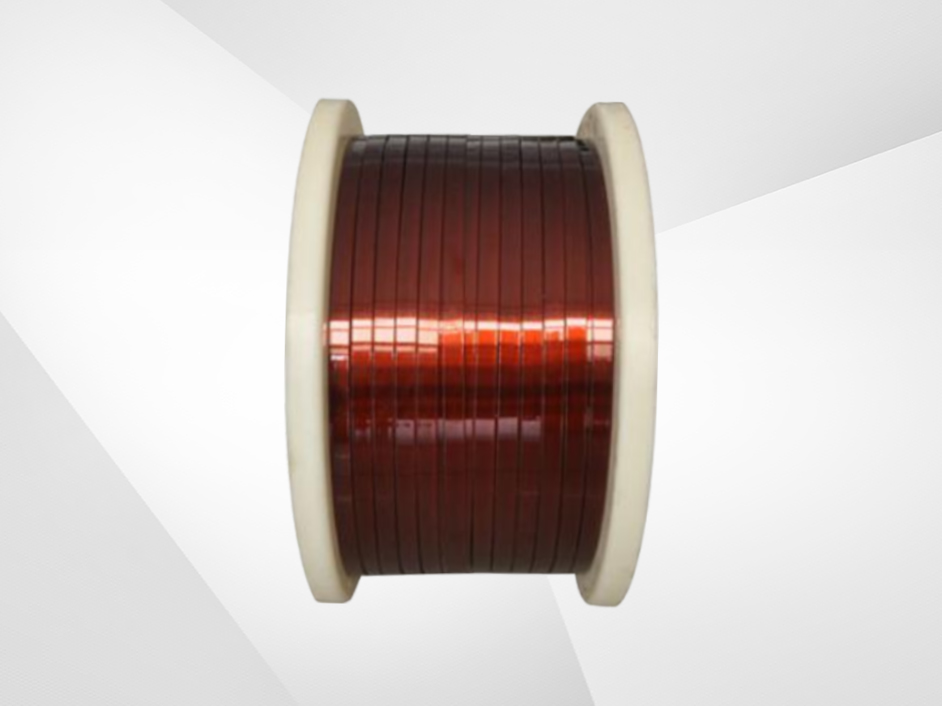

Enamelled Copper Flat Wire

- Details

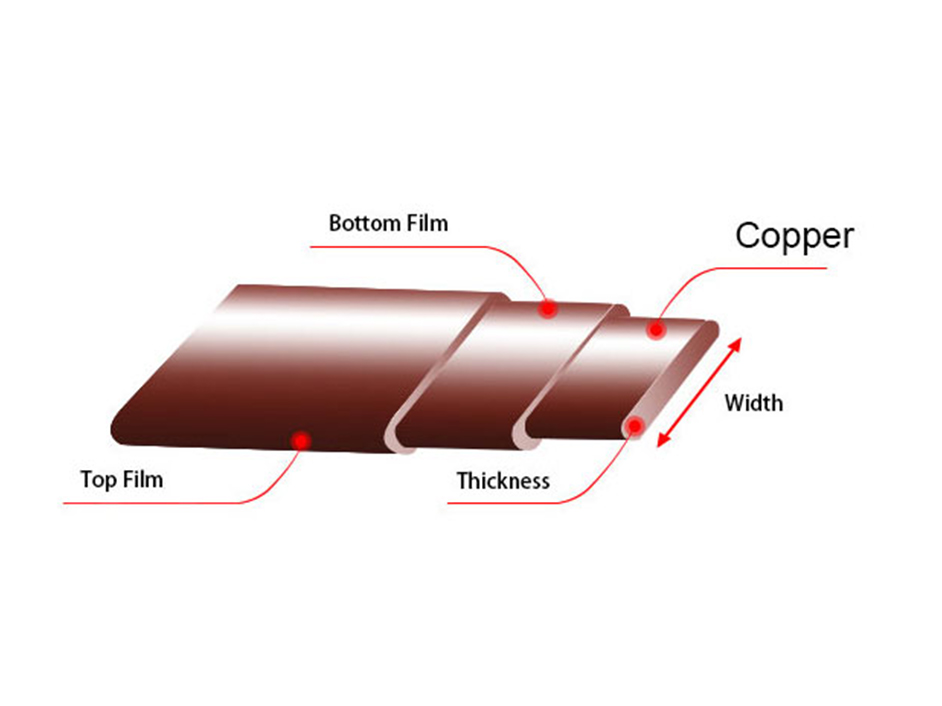

Enamelled flat wire is a enamelled wire with a rectangular conductor at an R Angle. It is described by the narrow edge value of conductor, wide edge value of conductor, heat resistance grade of paint film, thickness and type of paint film.

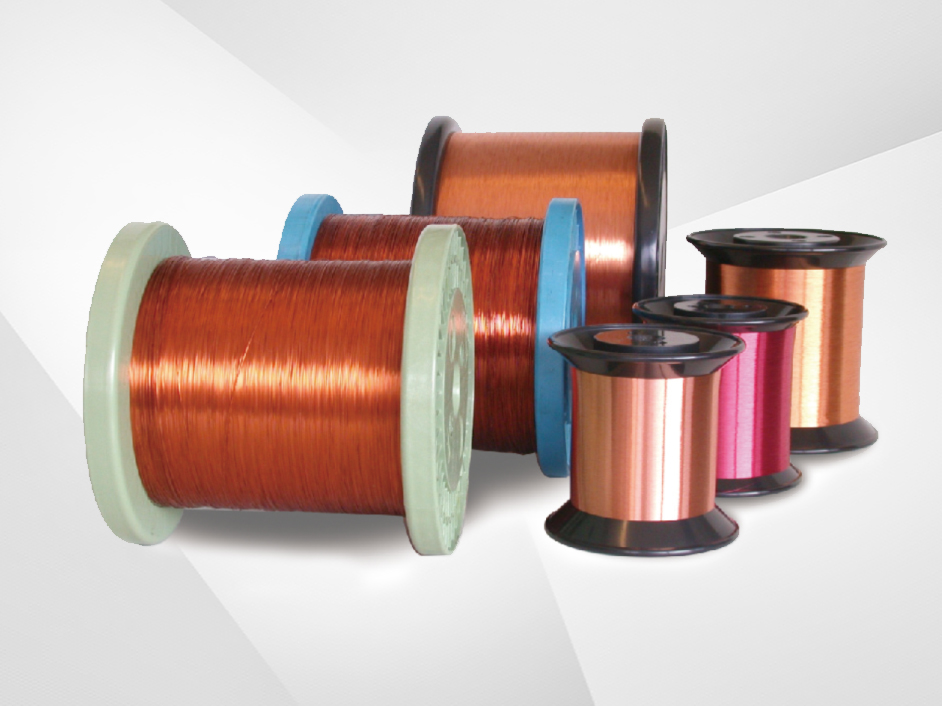

1.Material: Copper

2.Color: dark red

3.Uses: Enamelled flat copper wire is widely used, especially in the winding of various electrical equipment in telecommunications equipment, transformers, motors and generators

| Name | Enameled Rectangular Wire | ||

| Conductor | Copper | ||

| Dimension | Thickness(a):0.3~10.0mm;Width:1.0~22mm We can produce the Ultra-Flat Large Sizes wire | ||

| Thermal Class(℃) | 120(Class E);180(Class H);200(Class C);220(Class C+);240(Class HC) | ||

| Insulationthickness | Single,Heavy | ||

| Standard | IEC,NEMA,GB,JIS | ||

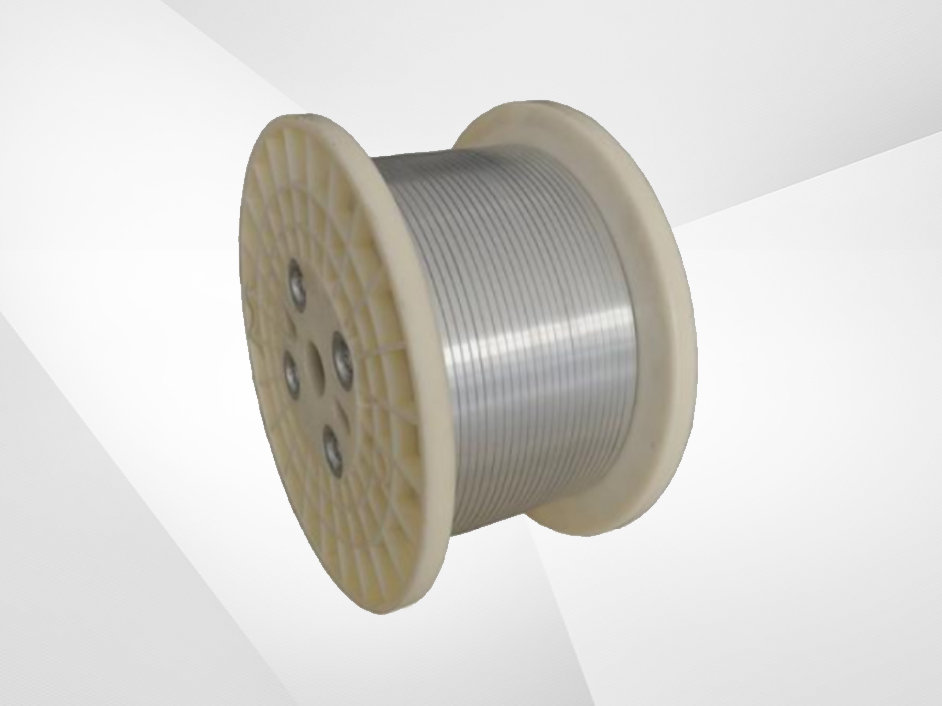

| Packing | 30kg ~150kg ply-wood spool(250*400/ 250*500/250*600/ 250*730 | ||

| Application | Transformer;motor;generator;modern instrument;welding machine and so on | ||

Model Explanation

Pay-off (drawing)→ annealing → painting → baking → cooling → lubrication → take-up repeat 1. Pay-off: the copper is uniformly released from the iron shaft to provide raw materials and ensure the stability of painting. In the high-speed machine, the joint drawing machine is relied on to pay-off. 2. Annealing: Soften the bare copper wire, remove the internal stress during the stretching process, rearrange the molecular lattice, and enhance the softness and conductivity. 3. Paint: Evenly paint the insulating paint to the bare copper wire, relying on molds or felt as a medium.

Our Advantage

* Excellent insulation and corrosion resistance

* Excellent electrical conductivity

* thermal stability

* scratch resistance

*solvent resistance

*wire resistance

*heat dissipation

*good magnetic field efficiency