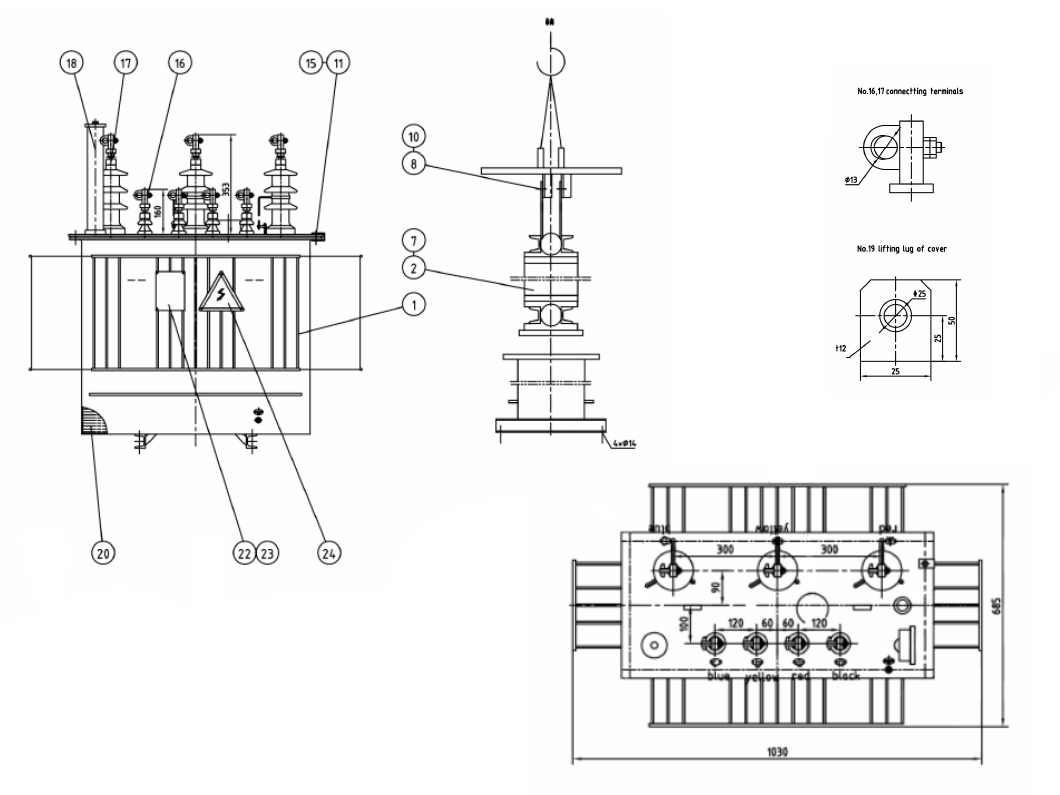

Oil-immersed Distribution Transformer Tank

- Details

The transformer adopts a fully oil-filled sealed structure, and the transformer changes its oil body due to changes in temperature and load, which is completely adjusted by the flexibility of the transformer tank. It has strong lightning resistance and short-circuit resistance. The energy-saving effect is more obvious, and the outer size of the transformer is reduced.

Product Features:

1.Low noise: compact design structure, application of new materials and new technology, reduce noise, no oil storage tank, lower height than similar products. There is no need to change oil during the normal life, which improves the safety and reliability of power grid operation.

2.Reliable long-term service life: The fully sealed transformer case cover and the tank rim are bolted or welded to isolate the contact between oil and air. The insulation will not be damp, which greatly reduces the insulation aging speed and improves the service life.

3.Small size and beautiful appearance.

4.No hanging core: The user does not need to check the hanging core before the fully sealed transformer is operated, which can save the cost of the hanging core inspection.

5.Maintenance-free: The fully sealed transformer does not require maintenance.

Product Standard:

GB/T 1094.1~2-1996 Power Transformer

GB/T 1094.3.5-2003 Power Transformer

GB/T6451-2008 Technical Parameters and Requirements for Three-phase Oil-immersed Power Transformers IEC60076

Applicable Environment:

High ambient temperature: +40℃

Low ambient temperature: -25℃

Altitude: <1000m. We can also customize according to your demand.

Monthly average relative humidity: 90% (20℃)

Installation location: Chemical plants, factories, remote places and other harsh environments.

| Rated capacity (KVA) | Voltage | Connection group tab | Loss | No-load current (%) | Resistant voltage | Weight | Measure(MM) | ||||||

| High-voltage (kv) | Extend connection | Low-voltage (kv) | No-load | Load | Empty weight | Oil weight | Total weight | Length* Width | Height (H) | ||||

| 20 | 6 | ±5% | 0.4 | Yyn0 or Dyn11 | 105 | 480 | 3 | 4 | 135 | 75 | 280 | 1075*695 | 910 |

| 30 | 6.3 | (±2×2.5%) | 130 | 600 | 2.1 | 175 | 85 | 335 | 1105*700 | 950 | |||

| 50 | 10 | 170 | 870 | 2 | 215 | 75 | 360 | 775*775 | 945 | ||||

| 63 | 10.5 | 200 | 1040 | 1.9 | 275 | 105 | 470 | 1170* | 1065 | ||||

| 80 | 11 | 250 | 1250 | 1.8 | 280 | 90 | 455 | 820*820 | 980 | ||||

| 100 | 290 | 1500 | 1.6 | 315 | 95 | 500 | 820*820 | 1005 | |||||

| 125 | 340 | 1800 | 1.5 | 365 | 105 | 580 | 850*850 | 1045 | |||||

| 160 | 400 | 2200 | 1.4 | 425 | 110 | 660 | 1135*1135 | 1075 | |||||

| 200 | 480 | 2600 | 1.3 | 500 | 130 | 775 | 1190*1190 | 1120 | |||||

| 250 | 560 | 3050 | 1.2 | 595 | 150 | 915 | 1215*1215 | 1140 | |||||

| 315 | 670 | 3650 | 1.1 | 700 | 170 | 1075 | 1285*1285 | 1200 | |||||

| 400 | 800 | 4300 | 1 | 865 | 195 | 1280 | 1305*1305 | 1285 | |||||

| 500 | 960 | 5150 | 1 | 985 | 220 | 1490 | 1455*1455 | 1275 | |||||

| 630 | 1200 | 6200 | 0.9 | 4.5 | 1140 | 250 | 1735 | 1555*1555 | 1285 | ||||

| 800 | 1400 | 7500 | 0.8 | 1400 | 290 | 2110 | 1660*1660 | 1375 | |||||

| 1000 | 1700 | 10300 | 0.7 | 1560 | 400 | 2475 | 1685*1685 | 1550 | |||||

| 1250 | 1950 | 12000 | 0.6 | 1915 | 465 | 2985 | 1805*1805 | 1505 | |||||

| 1600 | 2400 | 14500 | 0.6 | 2330 | 530 | 3745 | 1840*1840 | 1690 | |||||