Copper Aluminum Continuous Extruding Production Line

If you are interested in our products or need technical supports and service,please contact us as bellowing:

- Details

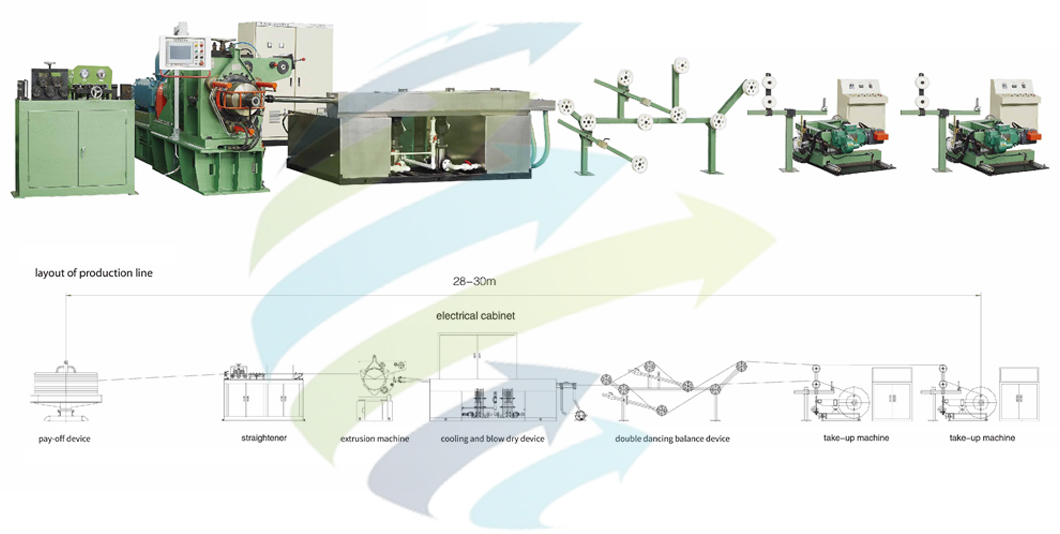

Copper Aluminum Continuous Extruding Production Line

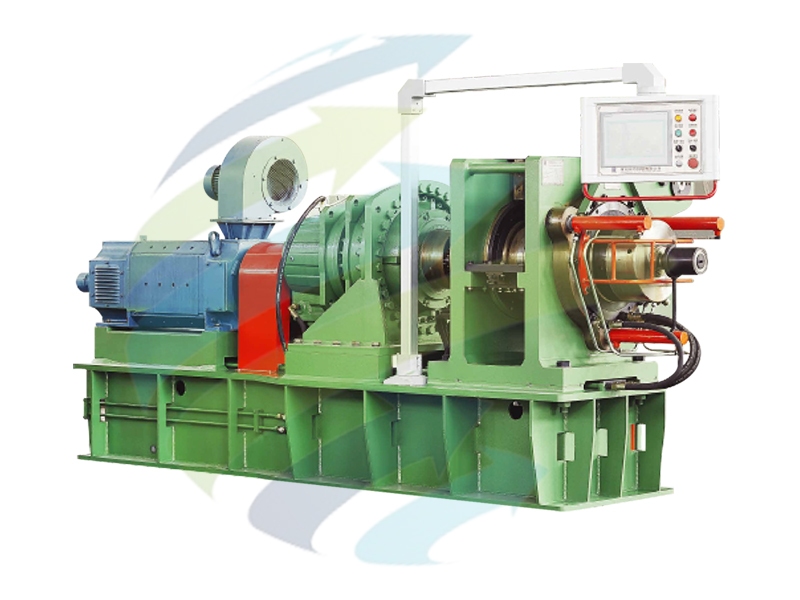

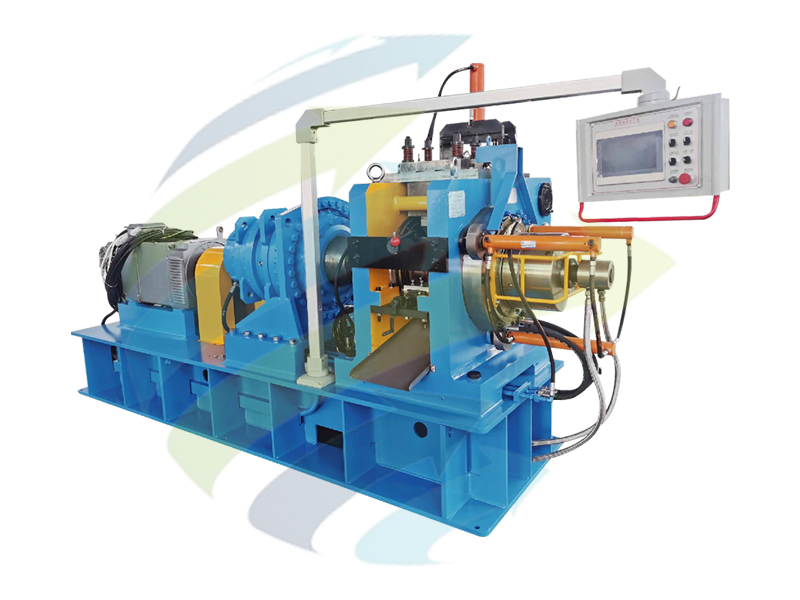

This production line is composed of pay-off stand for copper rods,straightener,continuous extruder,oxidation preventive cooling system,spooling machine and electrical controlling unit.Use pure copper rod without oxygen produced with pulling method as stock,different kinds of copper alloy rod can be used also.Copper rod cleaning system can not be used when the surface of the copper rod is clean.The stock wire is first given out from pay-off stand,then straightened and sent to the continuous extrusion host machine for extruding.Wire product form after extruding,then pass through oxidation preventive equipment and cooling system,the last step is wrap-up or length fixed cutting after measured by meter counter and other equipment.Features:

1.Use pure copper with same specification as raw material,different kinds of copper alloy can also be used.It's convenient to prepare the material.

2.Annealing is not required as extrudng process cause thermal Deformation.The equipmen thas remarkable energy saving character and good uniform feature

3.The production methodology is simple because die arrangement is not required as one mold form the shape directly.It's convenient to change the mold.

4.With accurate dimensions and fine finish,our products possess very good mechanical property and electric conduction property.

5.It's especially suitable for mass varieties and small batches production because the production process is fast and convenient.You need only change one mold when changing theproduct.

6.With compact structure,the equipment occupies less land.The equipment as well as the factory building cost little investment,and the operating cost is small.

7.With lower labor intensity,the equipment need lessoperators and have the characters of energy saving,environment protection and less methodology loss

| TypeTBJ300 | Copper | Aluminum |

| Nominal diameter of extrusion wheel(mm) | 300 | 300 |

| Power of main motor(kw) | DC90KW or Servo motor 90KW | DC110KW or Servo motor 110KW |

| Rotating speed of extruder(rpm) | 4~12.5 | 4~18 |

| Type of material | no oxygen up-casting copper rod | Aluminum rod |

| Diameter of wire rod(mm) | φ12.5+0.2 | φ9.5or φ12 |

| Maximum width of the product(mm) | 50 | 40 |

| Sectional area of the product(mm²) | 5~300 | 5~200 |

| Flakiness ratio of finished product | ≤15:1 | ≤15:1 |

| Average productivity(kg/h) | 350~450 | 150~200 |

| Overflow rate(%) | 1~3 | 1~3 |