The Type of XS2 Dehydrating Breather

- Details

Dehydrating breather is a device used to remove moisture and desiccate the air within transformers or oil conservators of mutual inductors, Installed in the air inlet port of transformers or oil conservators of mutual inductors, it mainly works to keep the transformer oil dry and clean.

CONSTRUCTION

The top and the bottom sections are casted aluminum and electrostatic powder painted. The shafts are made of nickel plated steel and the sieves are made of zinc sheet. Container cylinder is glass or polycarbonate depending on the customers' request. Oil bowl is of polycarbonate and the bowl holder is made of CrNi material.

OPERATION PRINCIPLE

When the transformer gets air in, an air flow from and to the oil bowl occurs. The oil layer in the bowl prevents the dryer material from continuous contact with the damp external air and cleans the air flowing in. If the operation temperature of the transformer decreases, the volume of the isolation oil gets smaller. During this lessening, an amount of air equal to the lessening amount is absorbed in to the oil bowl through air holes. This air then transfers to the expansion vessel and contacts with the oil layer. During this transfer, air contacts with the dryer material and leaves its moisture there. With the heating of the oil in the transformer tank, the air inside flows out from the opposite direction of the moisture holder.

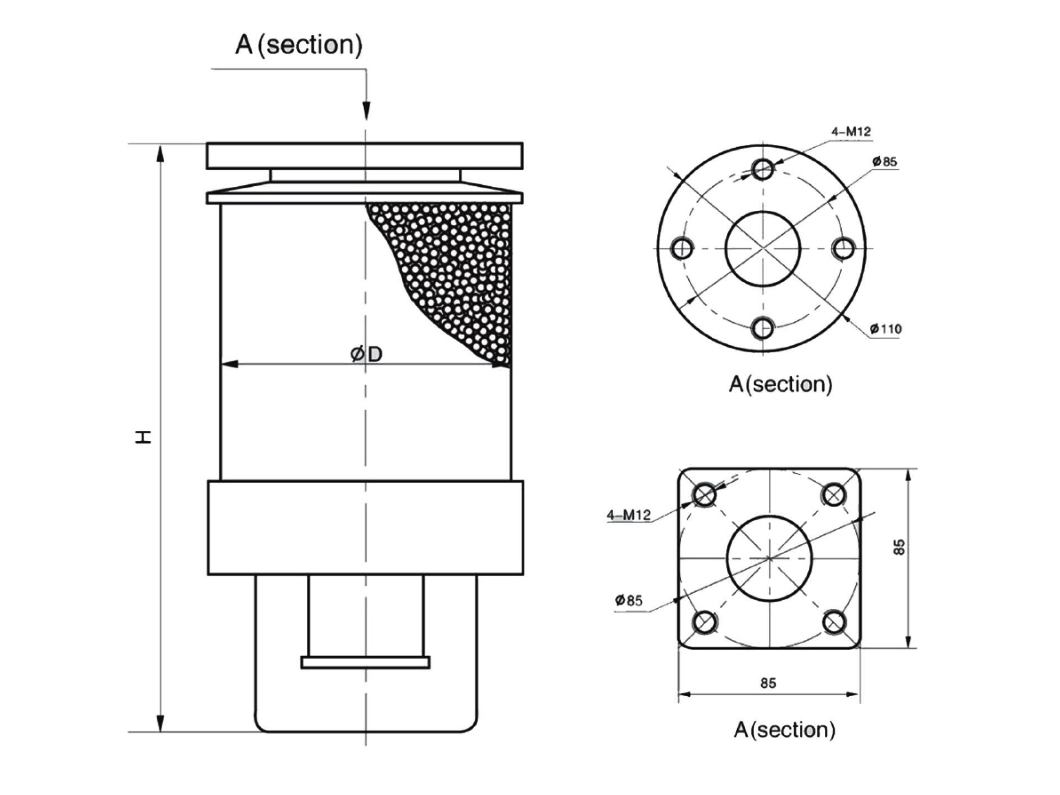

Technical parameter & external dimension

| Code | Type | φD | H | Silicagel weight(KG) | For transformer oil(KG) | Transformer capacit(KVA) |

| YC.685.1 | XS2—0.2 | 75 | 170 | 0.2 | 700 | Below 80KVA |

| YC.685.2 | XS2—0.5 | 90 | 200 | 0.5 | 1500 | Below 200KVA |

| YC.685.3 | XS2—1 | 120 | 260 | 1 | 3500 | Below 630KVA |

| YC.685.4 | XS2—1.5 | 120 | 300 | 1.5 | 5000 | Below 2000KVA |

| YC.685.5 | XS2—2 | 120 | 330 | 2 | 7000 | Below 3150KVA |

| YC.685.6 | XS2—3 | 165 | 355 | 3 | 10000 | Below 10000KVA |

| YC.685.7 | XS2—5 | 165 | 450 | 5 | 22000 | Below 50000KVA |

| YC.685.8 | XS2—10 | 165 | 680 | 10 | 35000 | Below 500000KVA |

Note: Flange installation method is selected by the customer, such as circular installation, add C after the code. For square installation, add S at the back. The type of silicone use is also specified by the customer.